YJ Quality, Trustworthy

Testing Mould

The company will cooperate with Delcam to implement the technical solution of machine quality inspection, so as to further improve the quality control capability.

Guarantee ability

The company has a sound quality management system and system. In daily work, the company pays attention to strengthening the quality awareness of employees, and regularly organizes monthly special training and improvement on quality defects and other issues. QC team is set up in the company to supervise every process of mould production and ensure product quality first.

Die Design Control

The company can provide product analysis and Mouldflow reports, and give customers timely feedback on the problems found on the drawings,

such as thin area, shrinkage mark, melt mark, blowhole, undercut, gate location, gate type, etc.

Mould material Control

Steel suppliers need to provide steel quality assurance and Material Certificate, Riverside Mould will be accepted before acceptance Do steel inspection.

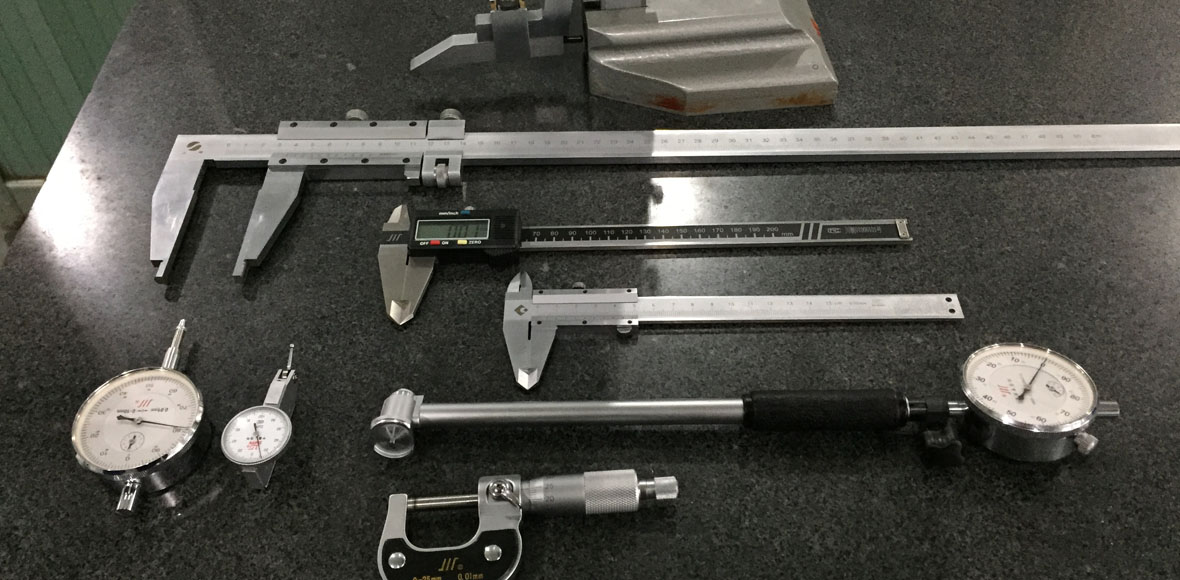

Mold processing Quality Control

Quality Control of Key Processes and Progress of Project Management It will be organized into written documents to provide customers weekly. Progress and quality report.

Purchasing and Control of Die Spare Parts

We will focus on qualified spare parts to meet customer requirements for standard parts type, quality standard and purchasing time of

.

Die Assembly Control

Physical treatment will be carried out in accordance with the established process and relative inspection will be carried out to strictly check the matching of core, cavity, insertion, guide